The Precision Craft of Diecasting: Revolutionizing Manufacturing

The Precision Craft of Diecasting: Revolutionizing Manufacturing

Blog Article

Diecasting is a highly specialized production process that transforms the hot metal into precisely-defined components using high-pressure molds. This technique has become indispensable in a variety of industries, such as electronics, aerospace, automobiles, and consumer goods, due to its capacity to create complex forms with incredible accuracy and consistency. By combining the principles of metals with modern engineering diecasting can provide unrivalled accuracy and precision, which makes it a cornerstone of contemporary manufacturing. This article delves into the complex world of diecasting by studying its processes, benefits as well as the wide range of applications.

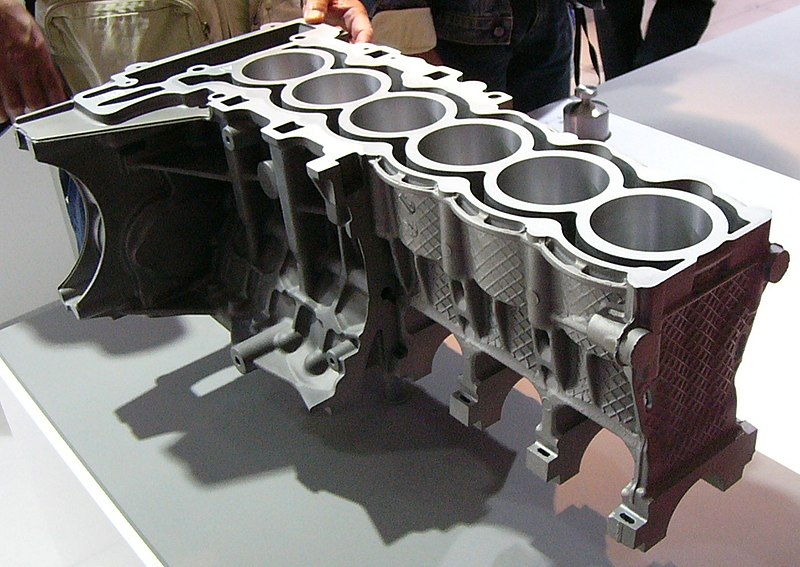

In the center of diecasting is the mold, known as a"die," which has been meticulously designed from solid steel, which is hardened to resist any extreme elements of the casting process. The layout of the die is vital, since it must accommodate the molten metal's flow and hardening while maintaining tight tolerances for precision. The process of casting dies, metals such as magnesium, aluminum, zinc, and copper are heated till they are molten. This molten metal is then placed into the mold cavity with high pressure, and fills every nook and cranny of the mold. The quick cooling and rapid hardening of the material result with parts that show exceptional dimensional accuracy as well as a smooth surface finish, often eliminating the need for additional processing or finishing.

One of the primary advantages of diecasting is its effectiveness in the production of mass quantities. When the dies are made and the process begins, it is repeated thousands or hundreds of times with minimal variation between components. The high degree of repeatability is essential when it comes to industries that require massive amounts of the same components. Diecasting is also known as a material that is efficient. This process produces lower waste than other metal forming techniques since excess metal is able to be recycled and used again. This is not just a way to reduce the cost of material but also contributes to greener manufacturing practices. A combination of speed, precision, as well as material efficiency make diecasting a viable solution for manufacturing large quantities.

Diecasting is also an excellent method for creating products with exceptional mechanical properties. The rapid cooling of the melting metal in the casting process produces an extremely fine-grain design, which increases the durability and strength of the final product. Dies makes diecast parts suitable for applications that require superior performance and durability. For instance, in the automotive industry, diecast parts are used in transmissions, engines and structural elements, where the strength-to-weight ratio is crucial for safety and vehicle efficiency. Similarly, in aerospace diecast components aid in the development of lighter but solid structures, which are crucial to improving fuel efficiency and performance. To obtain new information kindly look at Senadiecasting

Diecasting materials play a crucial role in determining the properties and the performance of the final product. Aluminum is among the most popular materials used because of its superior strength-to-weight ratio, its resistance to corrosion and excellent thermal and electrical conductivity. Zinc alloys are also popular, offering high toughness, ductility and the ability to produce pieces with intricately detailed detail. Magnesium alloys have the benefit that they are the tiniest structural metal. This makes them perfect for use in areas in which weight reduction is essential. Copper alloys, though less common, are used due to their high electrical conductivity and corrosion resistance. The choice of material depends upon the specifications of the use, including mechanical properties, environment conditions and price factors.

Diecasting is an incredibly efficacious and versatile manufacturing process which helps in creating complicated metal parts that have consistent and high-precision. Its ability to create parts with intricate details, tight tolerances, and flawless surface finish makes it invaluable across various industries, from automotive and aerospace, to consumer electronics, as well as beyond. Utilizing different types of materials also enhances the utility of diecasting. This allows manufacturers to pick the right alloy to suit their requirements. As technology advances and demand for high-quality, efficient components grows the use of diecasting will be crucial in the manufacturing landscape which will drive innovation and superiority when it comes to production.